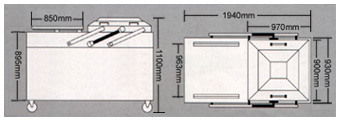

NN-777

The Vacuum Air Inflating Packing Machine

or edges to trap any dirt possible. It is easilyrinsed by applying formy water as well as disinfectant.

*User friendly operator interface

Built-in water tight, washable keypad microprocessor control of 10 programmable memory. It regulates the packaging process in automatic mode. All are displayed in graphics and digital makes the operator easily dialogue with the equipment. The operators touch and select the program number and the packaging cycle is set automtically.

*Automatic lid swing

The kid swing device move the lid to right and left chamber according to the evacuation cycle set-up by built-in water-proof microprocessor control programs, with help of its integrated vacuum sensor, the packaging process is carried out automatically. By pushing a button, automatic or single cycle operations, it largely reduce labor work and increase output.

*Seal unit equipped with two parallel, twin seal wire

The machine is equipped with standard single twin seal wire of 6 mm width at the lower bar, with additional seal pressure to guarantee an even and secure seals on all kind of bag materials.

*Vacuum pump

A built-in vacuum pump selected with a capacity of 160, 190 or 250 m3/h could be equipped. Or and external supply of vacuum system is available as well. The patented vales are used, reliability of a vacuum is guaranteed.

*Filler plates

It is made from rigid PE plastics to support the bags, particularly when flat, solid products are packed. And it also help speed up the evacuation cycle by reducing the chamber volume.

Optional features

*Gas flushing device

the machine can be equipped with inert gas flushing unit upon request.

*Double sealing bars

Sealing heat is applied to the pouch from both bottom and top sealing bars if aluminum bags are being packed.

*own custom Specifications |